May 15th 2020

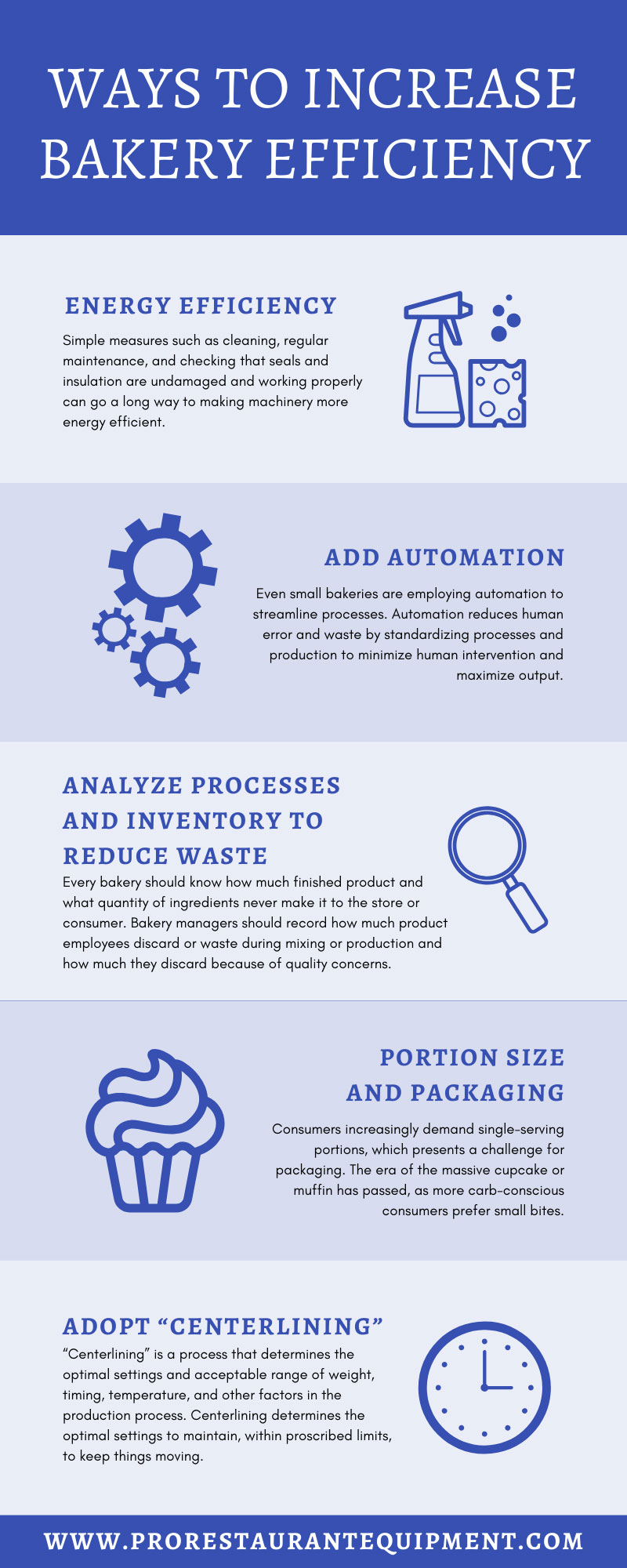

Ways to Increase Bakery Efficiency

All bakeries, from small storefront operations to large commercial producers, benefit from increased efficiency. It’s easy to get caught up in the repetitive rhythm of bakery production, without noticing where processes could be improved to streamline production and reduce costs. When one unexpectedly large order or a sudden increased demand for a popular bakery item consumes more resources than planned, efficiency suffers. Likewise, when unpredictable, external factors like COVID-19 disrupt all ordinary operations, bakeries may have to scramble to use up perishable ingredients, creatively move product, and retain employees. Where local containment measures permit, some bakeries have shifted to curbside pick-up or delivery to move product and retain employees. Here are some other ways to increase bakery efficiency that could save money, increase sales, and ultimately, boost profits.

Energy Efficiency

Ovens require a lot of energy. Hot ovens waiting for batches are wasting enormous amounts of costly energy, compounded by heat loss through flues and exhaust. Newer, more energy-efficient ovens combined with streamlined baking processes can reduce costs while maintaining product quality. Innovations like infrared and multi-level ovens or specialized reflective coatings reduce heat waste and facilitate faster batch processing. Heat-recapture technologies redirect vented heat for other uses, such as heating water. Some utilities offer energy audits to identify areas in the bakery building that operators can modify to improve energy efficiency. If the local gas or electric company doesn’t offer this service, private energy efficiency consultants might help.

Simple measures such as cleaning, regular maintenance, and checking that seals and insulation are undamaged and working properly can go a long way to making machinery more energy efficient. Safety must be the paramount concern, and any modifications must, of course, comply with safety regulations so that employees don’t get exposed to dangerous conditions in the name of efficiency.

Even adjustments in humidity can improve product and efficiency. Ultrasound humidification technology improves energy efficiency while maintaining bread quality. This process matches humidity levels between fermentation and baking, preventing dough from losing moisture and resulting in a higher-quality, more consistent product.

Add Automation

Even small bakeries are employing automation to streamline processes. Automation reduces human error and waste by standardizing processes and production to minimize human intervention and maximize output.

Smart monitors can provide data that will give bakeries insight into energy use. Smart monitors gather real-time data from machinery and building systems and send it for cloud-based analysis to identify inefficiencies in ovens, cooler, and HVAC systems.

Although ovens, coolers, and boilers use most of a bakery’s energy, it would be a mistake to ignore the bakery building itself when doing an energy audit. Insulation, water use, HVAC systems, and lighting all come into play.

Smaller bakeries might consider introducing automation in stages. Depending on the individual bakery, its specialty products, and its customers’ preferences, a combination of automated and manual processes may still work best. A step-by-step improvement process, upgrading machinery gradually, might prove most efficient. For example, moving from a countertop to a larger floor version of commercial dough sheeter might be enough to boost production and turn out more products in less time.

Analyze Processes and Inventory to Reduce Waste

Every bakery should know how much finished product and what quantity of ingredients never make it to the store or consumer. Bakery managers should record how much product employees discard or waste during mixing or production and how much they discard because of quality concerns. Still more product is wasted simply because it didn’t sell. The ideal is to have just the right amount of ingredients available to produce just the right amount of product with minimal waste.

Concurrently, managers should look at inventories of raw materials and figure out if they’re over-ordering. If ingredients are going unused to the point they get discarded, then clearly something has gone wrong: The bakery either isn’t producing as much as planned or isn’t producing products as quickly as anticipated. An inventory control system based on the “just in time” concept can help bakeries manage the flow of ingredients into finished products, and the delivery of just the right amount of product at the right time.

The number of people involved in producing various bakery items, and the role each person plays, are critical in efficient bakery operations. Inefficiencies may lie in things as simple as the number of steps it takes a worker to cross the bakery floor to transfer a batch of bread into an oven or to retrieve ingredients from storage.

Synchronizing batches and addressing lag time between batches, to identify the most efficient process and sequence for producing slower batches and managing downstream bottlenecks, is another way to address inefficiencies.

Of course, many bakery products simply require patience—popovers, muffins, breads, cakes, and cookies take as much time as necessary to produce dough, divide it into portions, and bake to perfection. Making a production schedule that accommodates the time each item needs, while preventing backup or lag time where a hot oven goes unused, is the science that perfects the art.

Portion Size and Packaging

Consumers increasingly demand single-serving portions, which presents a challenge for packaging. Adaptable packaging systems that can switch rapidly from, for example, packaging entire cakes and pies to packaging individual slices, will help bakeries meet consumer demand. The era of the massive cupcake or muffin has passed, as more carb-conscious consumers prefer small bites.

Adopt “Centerlining”

Bakeries that run shifts are subject to inconsistencies in operations. Experienced bakers have their preferred settings and methods, and managers respect their employees’ experience. However, inconsistencies in settings on machinery and minor adjustments to timing and temperature can add up to inefficiencies that increase costs. “Centerlining” is a process that determines the optimal settings and acceptable range of weight, timing, temperature, and other factors in the production process. Centerlining determines the optimal settings to maintain, within proscribed limits, to keep things moving. These settings are based on hard data, not human observation. Once bakery managers determine the most preferable settings, they can “lock in” those settings, while continuing to monitor production data and impose adjustments as necessary.

Bakeries of all sizes are involved in continuous improvement. Even “artisanal” bakers devoted to fully manual processes can find ways to improve bakery efficiency using smart monitoring and upgraded equipment.